However, I decided to keep the stock configuration of the extruder, because it’s a delicate and expensive part. The printer could be driven much faster designed with aīowden extruder. The mendelmin X carriage weighs about 0.5kg, which is a large mass with a lot of inertia.

Many modern RepRap designs use a Bowden extruder, where the filament drive motor and gearing sits elsewhere on the printer, and the X carriage The X carriage is compatible with my extruder, but it isn’t ideal. Torsional forces accumulate in the plastic and cause it to eventually tangle. Unfortunately the reality of coiled filament is that when it’s unspooled from the same side for long enough,

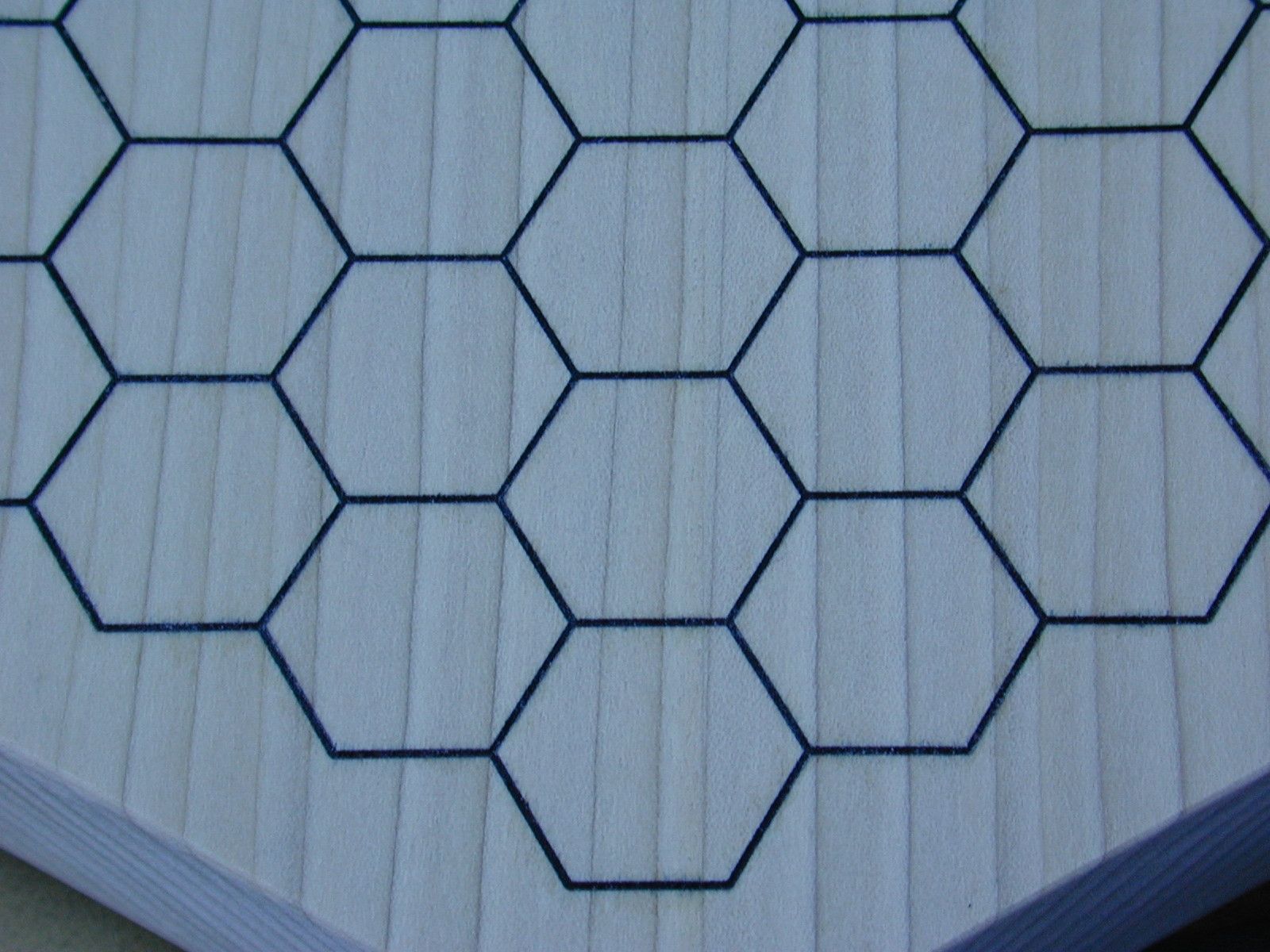

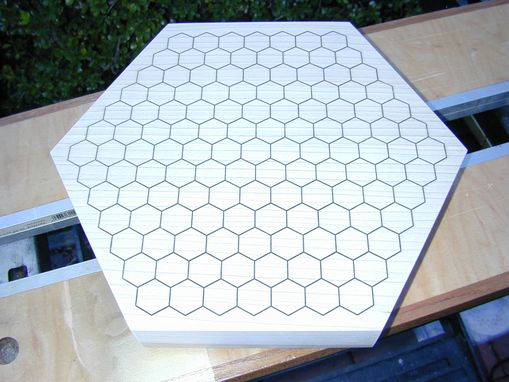

#The designm in the bottom of a goban upgrade

My filament feed system is an upgrade from my Prusa i2, because the spool can freely rotate. Bearings weren’t perfectly aligned, and the printer didn’t move smoothly. I originally designed the components to be printable, but upon printing them I realized that my design required more precision Is that one printer can make all the specialized hardware for another printer. It violates the core principle of a RepRap, which Resorting to laser-cutting components is a major failure for an open-source 3D printer design in my opinion, because very few people have access to a laser cutter. I added a housing forĪn LCD Smart Controller, which allows the printer to load files directly from an SD card, eliminating USB interference errors that used to happened at random and would ruin prints. The Z-wobble issue is solved, thanks to drive nuts that freely float inside the Z carriage rather than being rigidly constrained. The mendelmin has more print height,Ģ30mm up from ~60mm on the Prusa i2. That way, I could add on extras without interfering with the movement of the vertical axis. This could have been solved with some PTFE bearing surfaces,īut I decided I wanted to keep the aluminum frame empty. I experimented with using the aluminum sectionsĪs the linear guide for the vertical axis, but I found that there was too much static friction between acrylic and the aluminum. The frame is absolutely solid during prints, and happily, the printer is much quieter as a result, even while running 25% faster. Instead of a large double-decker base like the MendelMax, I have a single rectangular bottom frame, which gets extra rigidity from steel corner brackets, and T brackets at the vertical I moved the motors to the bottom of the frame, because top motors make it difficult to remove the X carriage assembly for maintenance. It uses a right angle design made of 2020 extrudedĪluminum sections, and laser-cut acrylic components.

Easier to assemble and disassemble without messing up calibration.Easier bed levelling and Z home calibration.No USB connectivity / interference errors.More frame rigidity: a more rigid frame allows the machine to print faster and more accurately.My Prusa i2, and transfer them to a simpler, stronger frame, while solving a number of other problems I found with the i2. I wanted a machine that would use the costly parts from There are a huge number of 3D printer designs out there RepRaps and all the variations on that principle. The Z axis was also over-constrained, which was a fundamental flaw in the design that made any eccentricity in the Z drive screws apparent as small ridges

The triangular prism shaped frame of the i2 meant that it was extremely difficult to make the machine With parts from the hardware store, but I felt that the design compromised too much. The Prusa i2 design of 3D printer I had built with my friend Eric in 2013 was a great little 3D printer that can be built

0 kommentar(er)

0 kommentar(er)